FINISHES

Non-Tactile Membrane Switches: The most economical membrane switch is the non tactile type. However, they do not give the user direct feedback from the switch. Using a LED indicator or display change can sometimes overcome this drawback. Non-tactile switches also have the advantage of easily creating custom shapes and sizes of the active keypad areas

Tactile Membrane Switches: Tactile membrane switches have a snap action that is clearly noticeable to the operator. Conductive stainless steel snap domes have the best action.

They can also eliminate the need for a flexible upper circuit layer. To ease the final mating of the switch and avoid the possibility of a dome becoming inverted a 0.015″ – 0.020″ backing layer can be provided. Because of the relatively short travel of membrane switches, it is often necessary to provide users with some type of feedback. Feedback can be visual, audible, or tactile. Visual or audible feedback should be a consideration in the electronics design. Dome switches can be added to a membrane switch to provide tactile feedback.

PCB Backed Membrane Switches: A printed circuit board can be used for the lower circuit. The board can provide structural support and incorporate numerous surface mount components. This assembly can be bonded to your PCB or sub-contractors can be utilized to provide this type of construction.

CONSTRUCTION AND DESIGN

Material Selection Polyester or Polycarbonate

Graphic overlays for membrane switches are commonly made from polyester material. This choice of material is essential because it provides the necessary flexibility for seamless membrane switch operation, ensuring that the overlay does not fracture or break under pressure. In contrast, polycarbonate is often preferred as a base material for decals, overlays, and labels where movement is not a factor. However, when it comes to membrane switch applications, polycarbonate is not the ideal choice due to its limitations.

Polyester films offer various advantages for graphic overlays, including the ability to have a gloss or textured hardcoat finish directly embedded onto the film itself. This feature enhances the aesthetic appeal of the overlays while also adding a layer of protection. Additionally, it is possible to incorporate texturing and gloss finish areas using UV silk screening techniques applied to the base polyester.

When considering outdoor applications, it is crucial to prioritize UV stability to ensure longevity and durability. In this regard, Autotex XE stands out as a recommended option due to its excellent UV stability properties. By utilizing Autotex XE for outdoor graphic overlays, you can be confident that the overlays will resist the damaging effects of prolonged sun exposure, maintaining their vibrant appearance and functionality over time.

For medical applications, a specialized option known as Autotex AM is available. Autotex AM offers an additional layer of protection by incorporating an embedded antimicrobial agent within the surface coating of the overlay. This feature helps inhibit the growth and spread of harmful microorganisms, making it an ideal choice for medical environments where cleanliness and hygiene are of utmost importance.

In conclusion, the choice of materials for graphic overlays is crucial in ensuring optimal performance and longevity. Polyester films provide the necessary flexibility, while options such as Autotex XE and Autotex AM offer additional benefits such as UV stability and antimicrobial properties, respectively. By considering these technical details and selecting the most suitable material for specific applications, manufacturers can create high-quality graphic

Circuit layers

There are two basic types of circuit layers that are used in membrane switch assemblies, PET and FPC. PET is a polyester where the circuit is laid out in silver ink and applied to the base material using a screen-printing process.

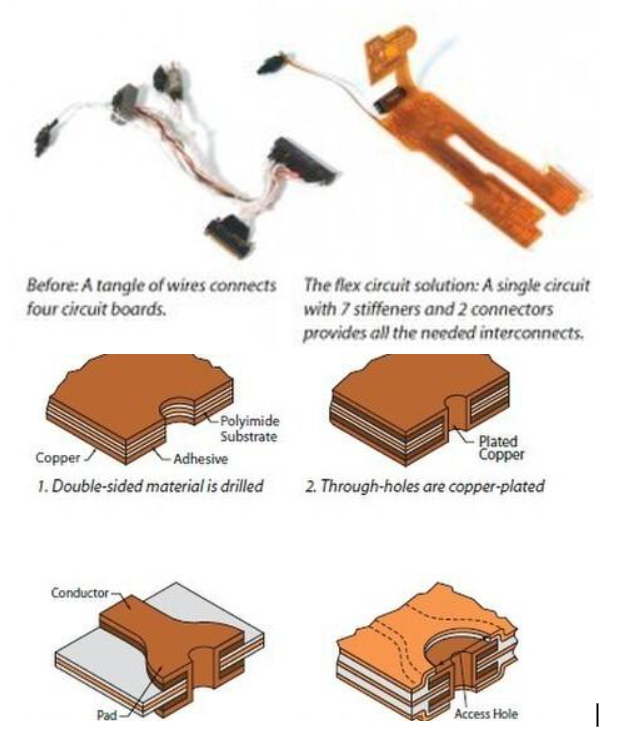

FPC or flexible printed circuit

FPC is a polyimide (Kaptron) base with a copper etch for the circuit, similar to traditional PCB manufacture but in a much thinner format and allows for soldering of components and connectors.

It is best suited for circuit pitches under 1mm (eg 0.50mm)

Design considerations of Membrane Keypads

- TACTILE WITH METAL DOME:

- Characteristics:

- Raw material: pressed stainless steel

- Plating: nickel, silver or gold

- Typical sizes range: 8 to 20 mm

- Typical actuation force: from 200 to 400 grams, depending on the type of dome selected

- Total travel: the distance on which the dome becomes deformed to create contact and close the circuit. It varies from 0.033mm to 1.17mm, depending on the selected dome size.

- Rebound duration: the time required for the travel to be carried out completely in one direction and then in the other varies according to the selected dome size.

- Lifespan: Typically from 1 to 5 million actuations

- Switching voltage: from 1 to 50 VCC

- Switching capacity: 1 Watt

- Switching current: from 0.005 to 100 mA DC

- Working temperature: from -45 °C to +100 °C

- Storage temperature: from -55 °C to +100 °C

- Advantages:

- Large variety of available sizes and actuation forces

- Excellent tactile effect

- Audible and tactile feedback

- Long lifespan

- Can be used at high temperatures

- Disadvantages:

- Requires a rigid surface of actuation in order to provide the expected performance.

- Can be damaged and cease to function if the membrane keypad is bent during application.

- Tactile effect is decreased if an excessive layer of raw material is placed on top of it.

NON-TACTILE: Non-tactile switches have no tactile or audible feedback. The closing of the circuit is done directly between the contact of the top circuit and the contact of the bottom circuit. The spacer/adhesive creates the required distance between the two circuits, in order to prevent permanent contact. The force of actuation is not determined by the type of dome, since there is no dome. The spacer thickness and configuration will determine the actuation force.

- Characteristics:

- Raw material: polyester and printed conductive ink

- Size and shape of the keys: varies according to the application

- Rebound duration and total travel: varies according to the application

- Lifespan: 5 to 10 million actuations

- Working temperature: from -40 °C to +85 °C

- Storage temperature: from -40 °C to +85 °C

- Advantages:

- Eliminates having to add mechanical components to the switch

- Extremely high lifespan

- Simple and cost-effective

- Applicable to large-surface keys of different shapes

- Disadvantages:

- No tactile feedback

- Audible feedback must be programmed on the module where the keypad is connected

- Not recommended if the graphic overlay has embossed keys

Membrane Keypad Quotation

Our preferred method for quoting is by submitting a 3D drawing in STP or IGES format, however we can quote if you have a 2D dimensioned drawing or sketch and direct discussion about your project requirements when drawings aren’t available.